Improvements in system efficiency results in lower energy consumption, increased production and lower cost in equipment maintenance. System efficiency improvements can be achieved by improving the flow distribution of devices including: fans, silencers, heat exchangers and flow mixers by decreasing the pressure drop across the duct system.

For example, a coal fired power plant used to burn high quality coal is changed to burn low quality coal; in order to keep the same power output, the flow rate has to be increased beyond the capabilities of the existing fan.

In this situation, the traditional solution is to buy a new higher capacity fan; this requires the size to be determined, the fan to be purchased and installed and an increase in electric power consumption which results in higher operating costs.

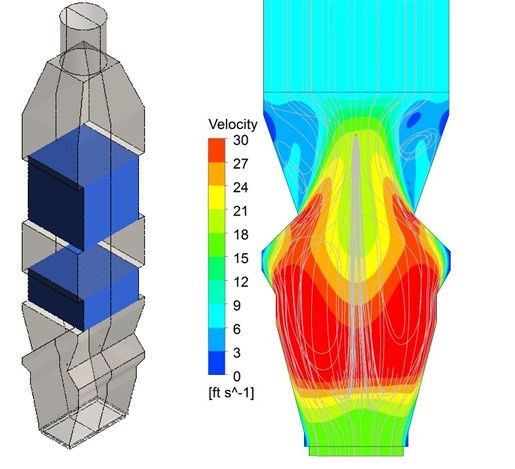

In many applications, a better solution is to undertake CFD simulation and consequently to modify the existing duct work to reduce the system pressure drop to enable the existing fan to meet the new requirement. This option does not increase operating costs and could reduce power consumption cost, giving the owner a better return on investment.