Confidence in aerodynamic performance needs to be qualified prior to costly wind tunnel testing, prototyping and releasing for production. The aerodynamic performance is an important indicator that the design needs are accounted for and correctly interpreted. VGE provides CFD analysis and simulations that validate:

- How the design will perform under real-world conditions:

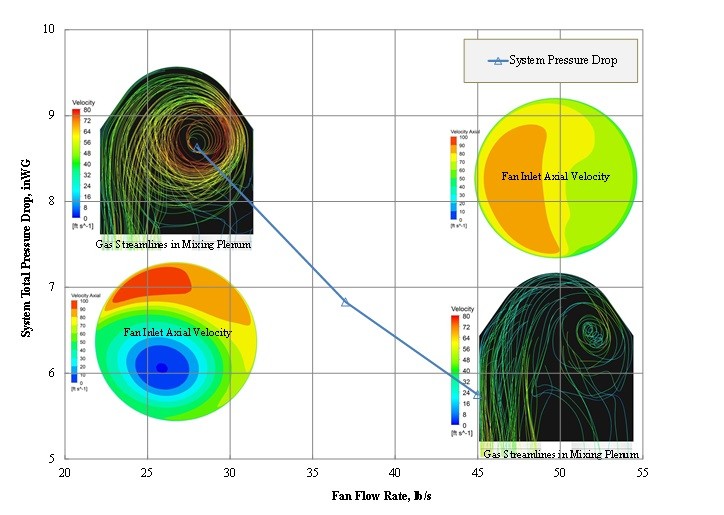

- What the flow distribution looks like

- How much the system pressure drop will be

- If enough heat transfer is achieved

- Whether the flow is stable

- CFD analysis provides design insight and highlights opportunities for optimization. Design Validation and Optimization provides customers with tremendous advantages:

- Cost Control – avoids overdesign, redundancy and costly rework

- Time to market – reduces time consuming testing with greater confidence

- Compliance – achieves designs that meet or surpass specifications

- Competition – providing better products than competitors