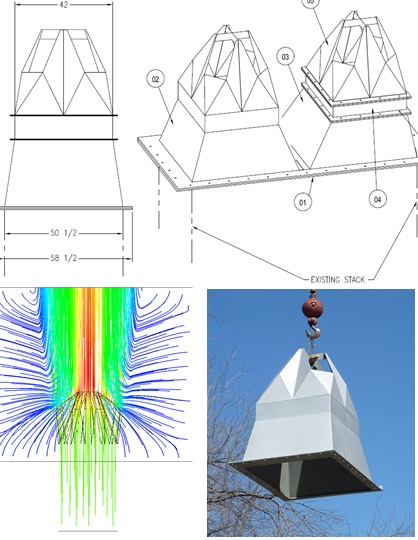

VG Engineering offer a range of custom designed steel

exhaust stacks in single and multi-flue configurations, covering a variety of applications and industries. Each is designed to customer and industry standards for the application to provide a cost effective solution.

Our stack designs are based upon proven engineering experience and use of class leading CFD, structural, thermal, dispersion and acoustical analysis software tools to ensure system efficiency and structural integrity for a long, low maintenance life based on the process medium, physical installation location and climatic conditions.

Exhaust stacks are fabricated and installed in accordance with our standard QA/QC procedures to insure that all processes, manufacture and assembly are to the highest standards. Dependent on the customer application exhaust stacks are fabricated in single or dual wall insulated configurations with base or side breach inlets, from mild steel, stainless steel or other alloys.

Duel wall liners include alloys suited to extreme operating environments.

A range of insulation liner materials can be provided to meet the process and medium requirements these include: glass fiber, basalt and ceramic

Protective finishes to suit the application and customer requirement are applied after the required surface preparation and include paint, epoxies and high temperature zinc coatings.

Dependent on the application and design we offer free standing self- supporting, guide wire or tower frame supports.

Exhaust stacks can be provided complete with:

- Expansion joints

- Access ladders, platforms or lifts

- Access hatches

- Emissions sampling/measurement and instrumentation mounting points