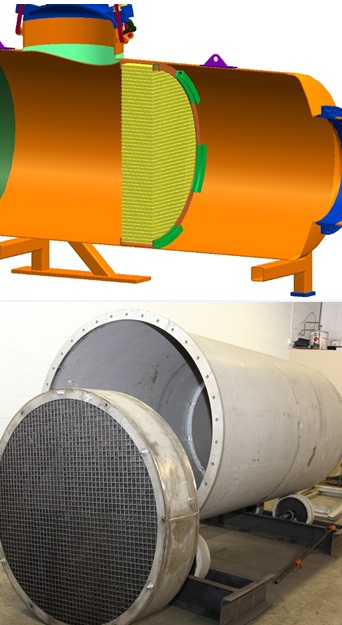

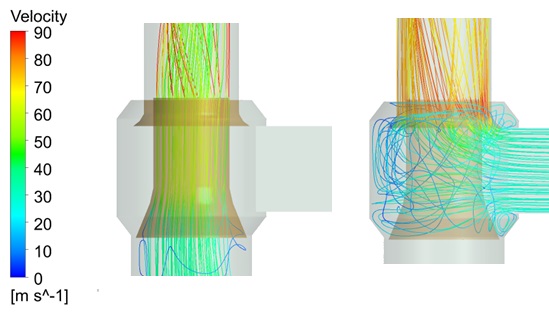

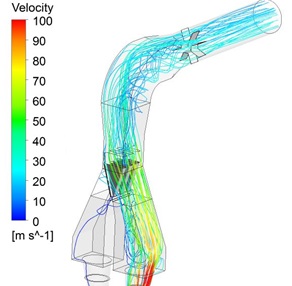

VG Engineering can provide acoustically lined and un-lined augmentor tubes for new, up-grade and retrofit applications. Augmenter tubes, sometimes referred to as detuners are designed according to operational use requirements such as; mass flow, temperature, velocity (Mach Number), vibration and sound. Augmentor tubes stabilize the engine efflux and provide adequate mixing of engine and entrained cooling air flow prior to noise attenuation through the silencer system. Correct design ensures that sufficient cooling air mass flow is provided for reliable operation without raising the test cell depression or effecting engine performance. Our augmenter tube designs allow for unstressed thermal growth while the fabrication uses suitable materials and technics to protect against elevated temperatures and thermal cycling together with corrosion caused by the combustion by-products. Where an acoustically lined system is required, a composite system of ceramics, basalt and high temperature e-glass are used to protect against thermal shock, vibration and erosion that are common issues especially in jet engine afterburner or reheat applications.